AI Summary

Amazon's new robot, Vulcan, incorporates "mechanical touch" and "physical AI" to sense and dynamically adjust its interaction with objects, learning from experience to handle approximately 75% of Amazon's inventory. Designed to work alongside human employees, particularly in ergonomically challenging areas like high or low shelves, Vulcan enhances efficiency and safety by performing tasks that are physically demanding for workers, marking a key step towards robots that can not only see but also physically sense their environment.

The typical warehouse robot today is essentially "numb and dumb," according to Aaron Parness, Amazon's director of robotics AI. Without tactile feedback, traditional robots face a binary choice when encountering unexpected objects: they either emergency stop or, worse, continue moving and potentially damage whatever they've contacted.

"In the past, when industrial robots have unexpected contact, they often don't even know they have hit something because they cannot sense it," Parness explains.

Think about when you drop a coin on the ground. The seemingly simple act of picking it up involves complex tactile feedback—you adjust finger pressure in real-time, sensing exactly when to clasp your fingers and how to manipulate the coin into your palm. For robots, this fundamental human capability has been largely unattainable—until now.

Vulcan's Mechanical Touch: How It Works

Vulcan represents more than just another iteration of warehouse robotics; it signifies what Amazon calls "a fundamental leap forward." Unlike its predecessors, Vulcan doesn't just navigate its environment visually—it physically interacts with it, understanding when and how it makes contact with objects.

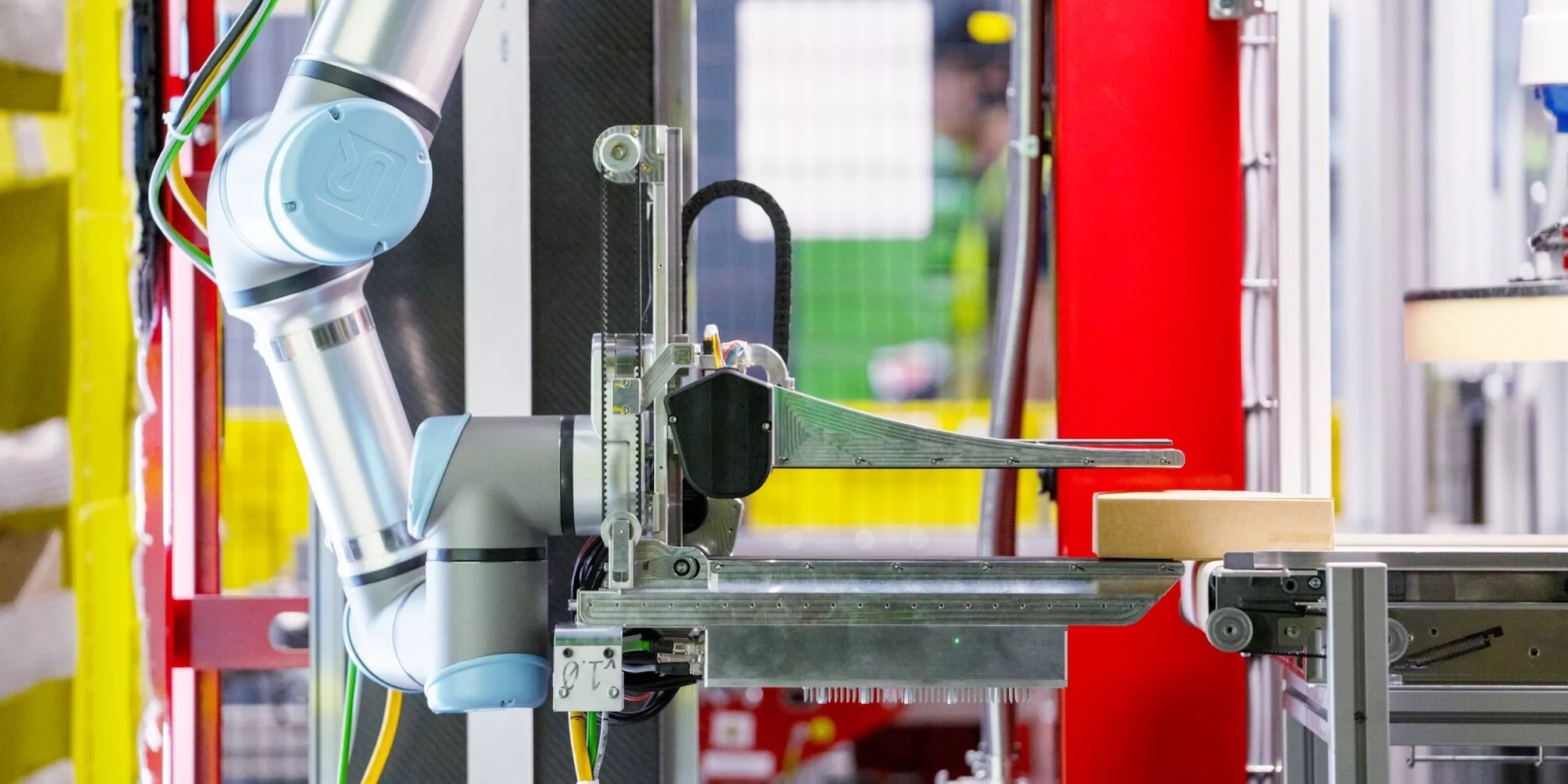

Its "hand" doesn't look particularly human. Instead, it resembles what Parness describes as "a ruler stuck onto a hair straightener." This unique end-of-arm tool serves dual functions:

- The "ruler" component pushes and rearranges items in storage compartments, making room for new additions

- The "hair straightener" paddles hold items with adjustable grip strength based on the item's characteristics, then use built-in conveyor belts to move items into bins

For retrieving items, Vulcan employs a different approach—an arm equipped with both a camera and a suction cup. The camera identifies the target item and determines the optimal grip point, while the suction mechanism secures and extracts it.

What sets Vulcan apart is its ability to dynamically adjust its interactions with objects. Just as humans modulate their grip strength when handling a delicate wine glass versus a sturdy cardboard box, Vulcan can sense how much pressure to apply to different items.

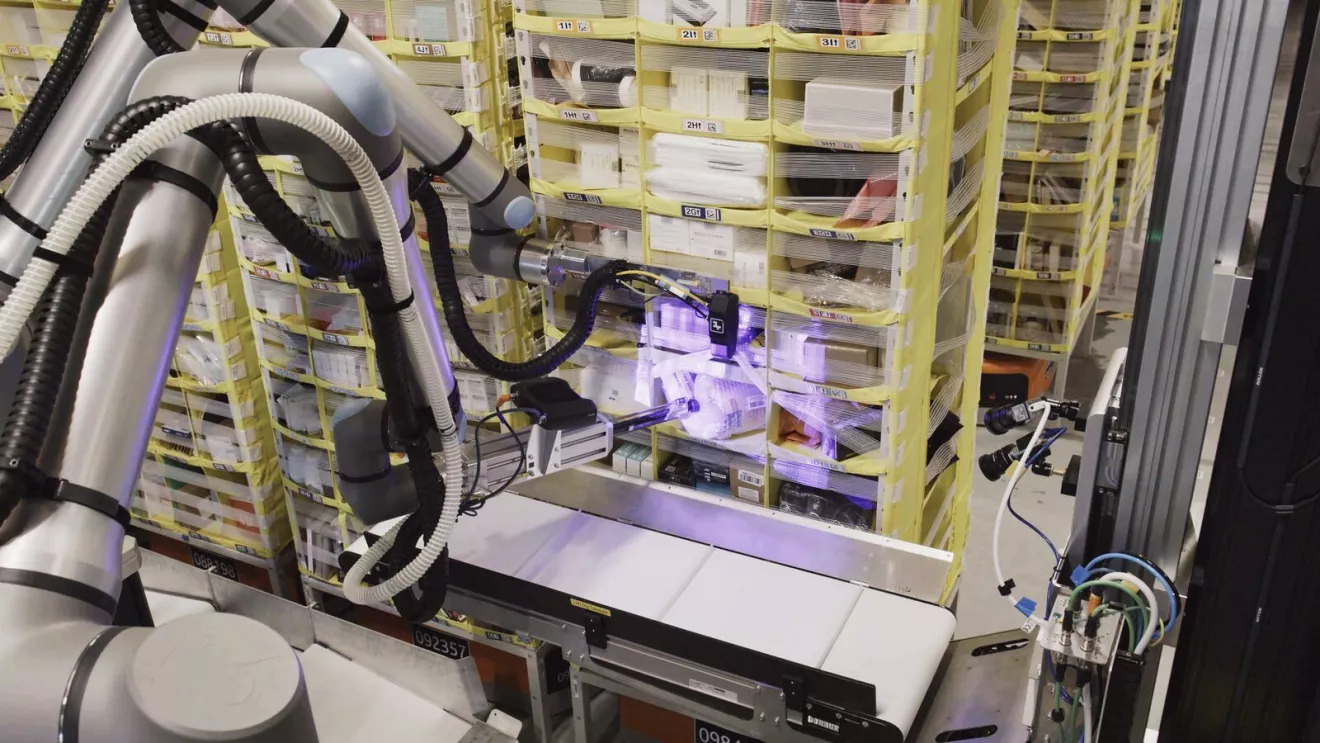

Perhaps most remarkably, Vulcan incorporates what Amazon calls "physical AI"—a system that learns from its own failures and successes. Much like how children build tactile understanding through physical exploration, Vulcan steadily accumulates knowledge about how different objects behave when touched.

This continuous learning loop means that Vulcan becomes increasingly adept at handling the millions of different products flowing through Amazon's fulfillment centers. Currently, the robot can handle approximately 75% of Amazon's vast inventory, with the intelligence to recognize when it encounters an item beyond its capabilities—prompting it to request human assistance.

The Human Element: Collaboration, Not Replacement

At fulfillment centers in Spokane, Washington and Hamburg, Germany, Vulcan is already operational, but its role is carefully designed to complement rather than replace human workers. The robot primarily handles items stored in the highest rows of inventory pods (approximately eight feet up) and those positioned near floor level. Parness said:

Vulcan works alongside our employees, and the combination is better than either on their own.

This strategic deployment addresses key ergonomic challenges. Before Vulcan, workers needed step ladders to access top-row inventory—a time-consuming and physically demanding process. Similarly, repeatedly bending to floor level introduces strain and fatigue. By focusing Vulcan on these ergonomically challenging zones, Amazon aims to keep human workers operating in their "power zone"—the mid-body region where lifting and manipulation are most comfortable and least likely to cause injury.

The Broader Impact: Jobs and Scale

Amazon's robotics strategy has consistently emphasized augmentation over replacement. Over the past 12 years, the company has deployed more than 750,000 robots into its fulfillment network, creating hundreds of new job categories along the way—from robotic floor monitors to onsite reliability maintenance engineers.

Programs like Career Choice provide pathways for associates to transition into robotics and other technical fields, potentially creating a pipeline of workers whose skills evolve alongside the technology. This addresses one of the most persistent concerns about warehouse automation: that robots will simply eliminate jobs rather than transform them.

The scale of Amazon's operation means that Vulcan's impact could be substantial. With robots already playing a role in fulfilling 75% of customer orders, the company plans to deploy Vulcan systems throughout Europe, the United Kingdom, and the United States over the next two years.

What's Next for Warehouse Robotics?

Vulcan represents a technological breakthrough that "three years ago seemed impossible," according to Parness. Its development suggests we're entering a new phase of industrial robotics—one where machines don't just see their environment but physically sense and interact with it in increasingly sophisticated ways.

This evolution mirrors the development of human senses. Vision came first to robots, allowing them to navigate spaces and identify objects. Touch represents the next frontier—enabling more delicate, responsive, and adaptive manipulation.

The implications extend far beyond Amazon's warehouses. Tactile sensing could transform everything from manufacturing to healthcare, enabling robots to handle increasingly delicate tasks with human-like sensitivity. Amazon's introduction of Vulcan raises intriguing questions about the future trajectory of warehouse automation:

- Will competitors follow suit with their own touch-sensitive systems?

- How might tactile abilities combine with other sensory inputs like enhanced vision or even sound?

- Could robots eventually develop full sensory integration comparable to humans?

- What new categories of jobs might emerge as these technologies mature?

For now, Amazon emphasizes that Vulcan's primary benefits are threefold: enhanced operational efficiency, improved workplace safety, and reduced physical demands on human workers. Translated to business outcomes, this means "getting the right product to right truck at ever faster speeds, allowing us to continue widening our selection and offer industry-leading prices."

Recent Posts